Parma, Italy, 04 October, 2024. IEC+, a leading mechanical engineering company, specialising in process equipment for dispersion, grinding, mixing, and filtration, has introduced the Plusmill Evo, the latest evolution of their renowned Plusmill.

Introduction to the Plusmill Evo

This innovative system integrates pigment dispersion and milling within a single unit, designed to meet the current and future needs of the ink and coatings sector. The Plusmill Evo significantly reduces waste, processing time, and contamination while optimising manufacturing processes and minimising health and financial risks.

"As the global industry’s requirements evolve, manufacturing processes need to adhere to exceptional control and cleanliness standards. However, traditional methods hinder productivity and compromise quality; this highlights the necessity for advanced solutions as technology advances,” explained Gianluca Incerti, Head of Strategic Sales at IEC+ and Tecnopails. “Our mission is to revolutionise crucial production processes by providing a simpler approach that enhances efficiency and quality in pigment manufacturing. That's why we have enhanced our already popular Plusmill with the new Plusmill Evo."

Key Features and Innovations

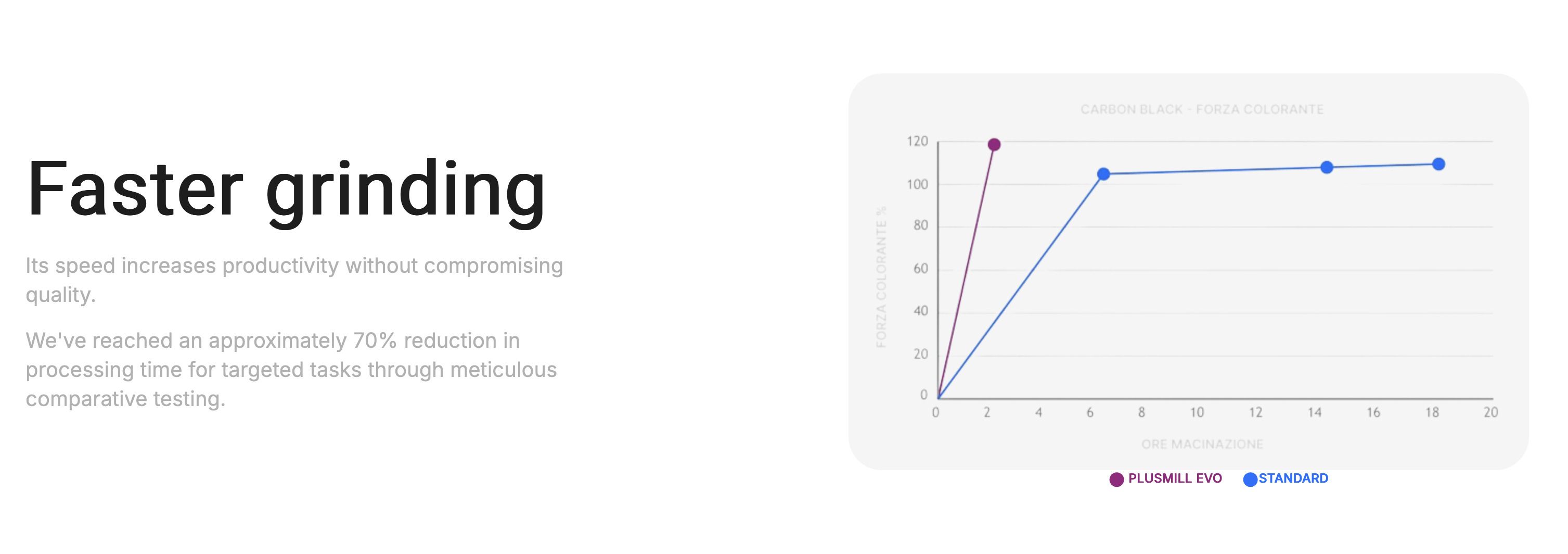

Setting new benchmarks for pigment processing, the Plusmill Evo offers precise control over dispersion and milling parameters, ensuring superior colour strength, consistency, and stability. The engineering team at IEC+ has dedicated several months to enhancing the system for efficiency, reliability, and a cleaner, safer working environment. Meticulous comparative testing has demonstrated an approximate 70% reduction in processing time for targeted tasks.

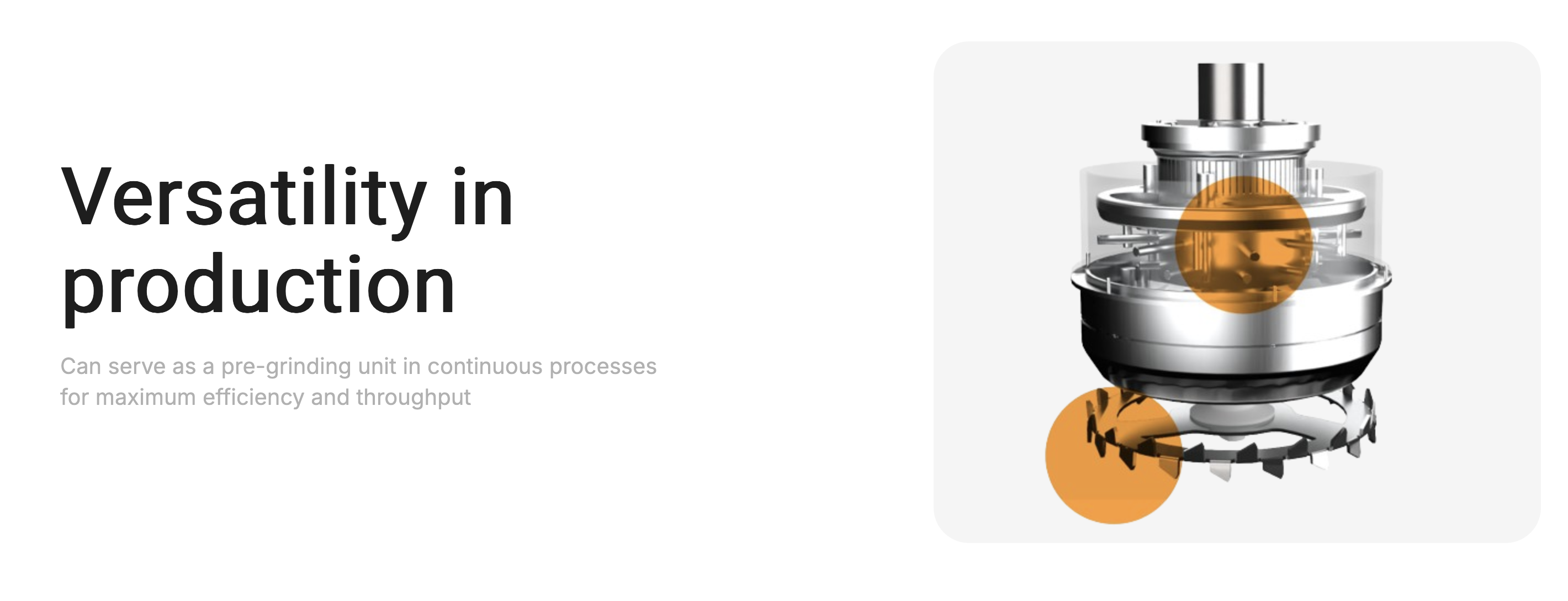

Integration of Cowles Impeller Technology

The Plusmill Evo introduces significant advancements, including the integration of Cowles Impeller Technology to enhance dispersion efficiency, guaranteeing thorough mixing of pigment particles with the liquid medium. This results in uniform particle distribution and flawless colour development, irrespective of industry standards.

Enhanced Safety and Efficiency

The new compact design minimises accident risks and protects operators from exposure to moving components, creating a broader and safer workspace. An integrated control system fine-tunes key parameters, such as particle sizes, to adjust the milling process for desired outcomes, while an Advanced Cooling System maintains optimal operating temperatures to preserve the integrity of the pigment dispersion.

Performance and Testing

“In essence, the Plusmill Evo accelerates operations, streamlines manufacturing processes, reduces the need for multiple machines, and cuts down setup and retooling times. Users can anticipate significant time-saving advantages and a rapid return on investment, with tangible benefits achievable within just 18 months of implementation," concluded Incerti. "When considering enhanced output, superior product quality, and decreased operational costs, the Plusmill Evo transcends being a mere investment—it stands as a strategic choice poised to yield dividends for years to come."

For more information, visit our dedicated landing page: Plusmill Evo Landing Page.

or contact Gianluca Incerti at sale@iecplus.com or tel: +39 0521 134 39 45.

About IEC+

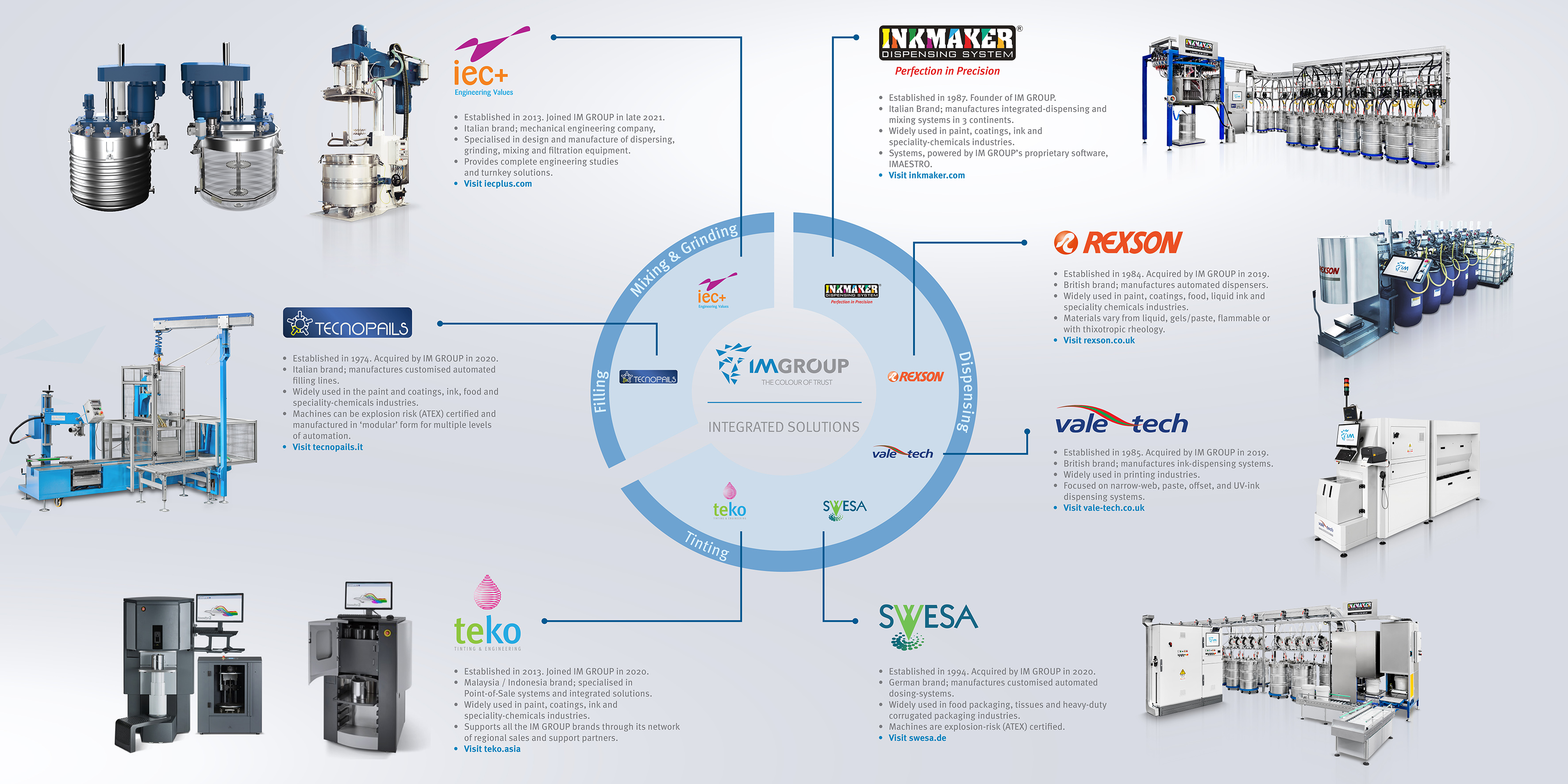

IEC+, which joined IM GROUP (formerly Inkmaker Group) in late 2021, specialises in designing and producing customised automated systems for dosing, sealing, and labelling for ink, paint, and chemical containers. Together with the Tecnopails filling-line division, it forms IM GROUP’s Filling, Mixing, and Grinding business unit.

Follow IEC+ on LinkedIn

About IM GROUP

Founded in Turin, Italy, on 22 April 2021, IM GROUP is a global leader in technology and engineering solutions, combining the expertise of its brands Inkmaker, Rexson, Vale-tech, Swesa, Teko, Tecnopails, and IEC+. The group offers comprehensive process engineering solutions, focusing on mixing and dispensing for various industries, including paint, coatings, ink, chemicals, adhesives, pharmaceuticals, cosmetics, and more. With a presence in 15 countries across five continents, IM GROUP is a trusted partner to Fortune 500 companies such as Boeing, Sherwin Williams, PPG, Akzo Nobel, Avery Denison, International Paper, and Tetra Pak.

To learn more about IM GROUP and its innovative solutions, contact us at IM GROUP

Follow us on LinkedIn

Published in the following international publications:

- Industry EMEA

- FoodPack Automation (EMEA)

- The Packaging Portal (UK)

- International Paint &Coatings Magazine_IPCM (Italy)

- LabelPack (Germany)

- PCI- Paint & Coatings Industry magazine (USA)

- Industry USA

- Paint & Pintura (Latin America)

- The Packman (India)

- Chemical Today (India)

- CP Mirror Magazine (India)

- Food Infotech (India)

%20v-4.png)

_IEC.png)

INKMAKER WINS 2024 CHINA TECHNOLOGY PIONEER AWARD FOR EASYPAINT SOLUTION

Dec 03 2024