Paintistanbul & Turkcoat Exhibition – 08 - 10 May 2024

Join us at at our agent Odak's booth A611 in HALL 3, at the Paintistanbul & Turkcoat Exhibition, Istanbul Expo Center, Turkey from 08 to 10 May 2024 and discover what’s new from IM GROUP and its partners.

For latest updates follow us on

Visit IM GROUP's booth at the Paintistanbul & Turkcoat Exhibition 2024.

The Paintistanbul & Turkcoat Exhibition is a significant gathering for the paint and coating industry worldwide. Turkey, ranking as the 5th largest paint producer in Europe with a market value of $164 billion, will unite industry experts and consumers. Organised in collaboration with the Paint Industrialists Association (BOSAD) and backed by the Turkish Chemical Manufacturers Association (TKSD), Turkish Construction Material Industrialists Association (İMSAD), and Additive Manufacturers Association (KÜB), this event serves as a focal point for professionals in the coatings sector. Anticipating over 8,000 attendees from more than 80 countries, it is a must-attend event for industry players.

During a span of three days, the Paintistanbul & Turkcoat Exhibition presents a wide array of cutting-edge products, technologies, equipment, and services. This includes an extensive range of offerings such as paints, coatings, laboratory and production equipment, packing and filling equipment, related services and much more.

We are thrilled to extend a warm invitation to you for this industrious event. Be sure to save the dates and join us at our agent Odak's booth A611 in HALL 3, where you can discover the most recent advancements of our solutions, our state-of-the-art software, and robust systems. We look forward to seeing you there!

About IM GROUP

IM GROUP (formerly Inkmaker Group) is a global technology leader headquartered in Italy, focused on reliability. It is the holding brand of: Inkmaker, Rexson, Vale-tech, Swesa, Teko, Tecnopails and IEC+.

IM GROUP combines the strength of each of its brands to offer integrated solutions across two specific business units: the Dispensing and Tinting unit and the Filling, Mixing and Grinding Unit.

IM GROUP's two business units are targeted at the industries of paint, coatings, ink, speciality-chemicals, adhesives, corrugated packaging, pharma, food, cosmetic, textiles and beyond. The group offers advanced integrated-engineering solutions, from design and manufacturing through to complete engineering studies and turnkey solutions for:

• Customised plant engineering and software design

• Highly accurate automated dispensing

• Process equipment from bulk handling to filling lines

• POS equipment

• and other related services

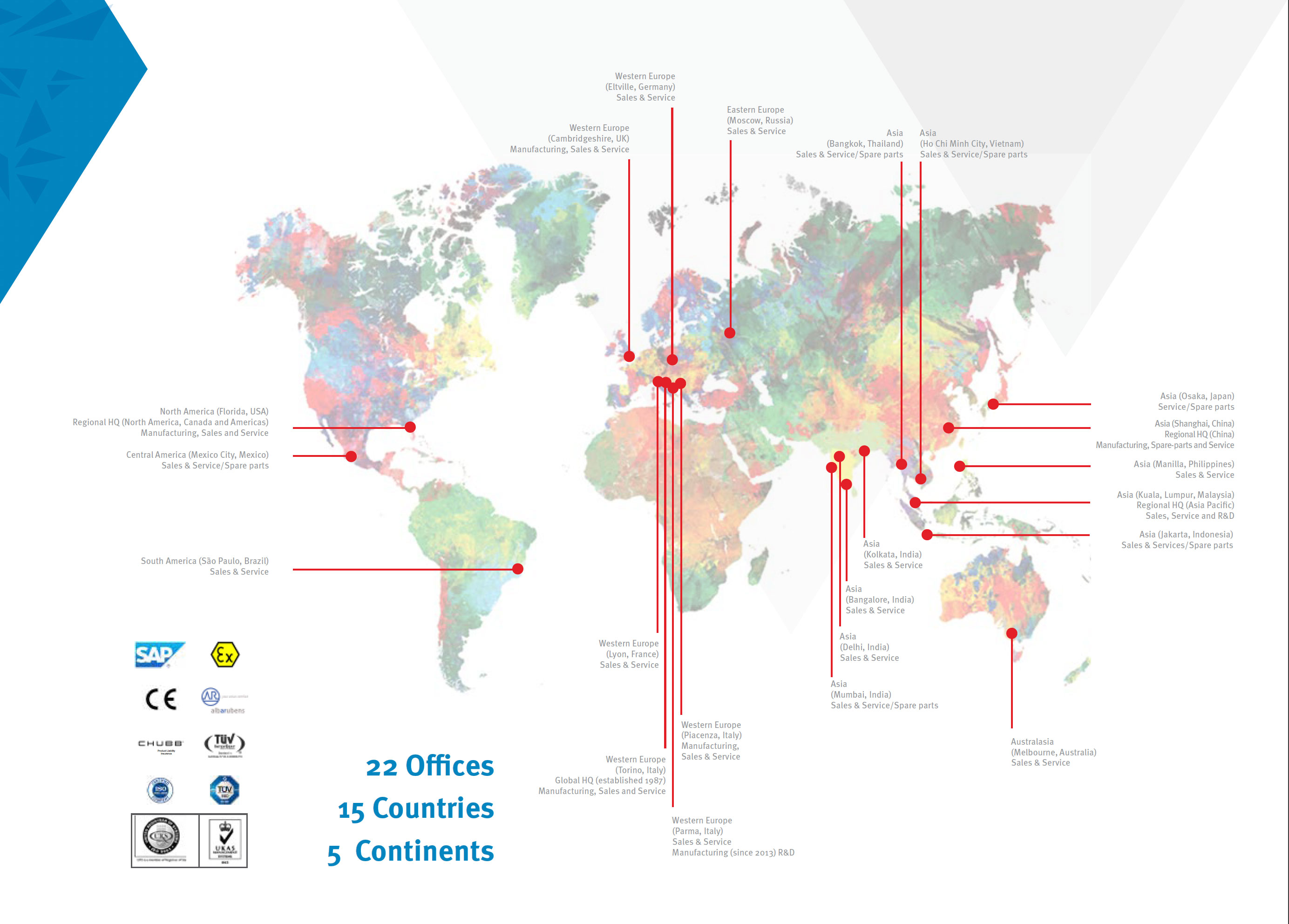

The group’s systems, manufactured in 3 continents are powered by the group’s state-of-the-art proprietary software, IMAESTRO, to guarantee highly accurate colours consistently, precisely and instantly. IM GROUP operates in over 15 countries throughout 5 continents.

Enquire about our renowned solutions such the P-Series by Inkmaker

Available in 32, 48, 72 or 96 multi-stage dispensing valves, the P-series machines have a patented centre-point dispensing, which can dispense into containers of any size. Valves are individually activated through a pneumatic cylinder, without rotating mechanical parts or motors, making the system extremely efficient and user-friendly.

or the convenience of the revolutionary ColorPoint™ by Rexson

With its cutting-edge dispensing station featuring 32 high-precision multi-stage dispensing valves, the ColorPoint™ offers easy inspection and replacement thanks to its 360°-access covers. This versatile system accommodates drums, IBC, and other vessels, allowing you to conveniently store and pump components to the dispensing head through a well-designed piping network.

Learn more about the PLUSMILL 2.0 Basket mill by IEC+

The Plusmill 2.0—the evolution of our popular Plusmill—is a dual-use vertical-immersion mill designed for fine and super fine dispersion and grinding,

To deliver high-grinding performances at faster speeds, the Plusmill 2.0 activates a revolutionary recirculation system; reduced beads generate turbulence within the basket, for grinding pigments. This innovation equips the mill with handling a wide range of viscosity products, and to deliver accelerated cleaning processes, reducing grinding time by up to 50%, to maximise R.O.I.

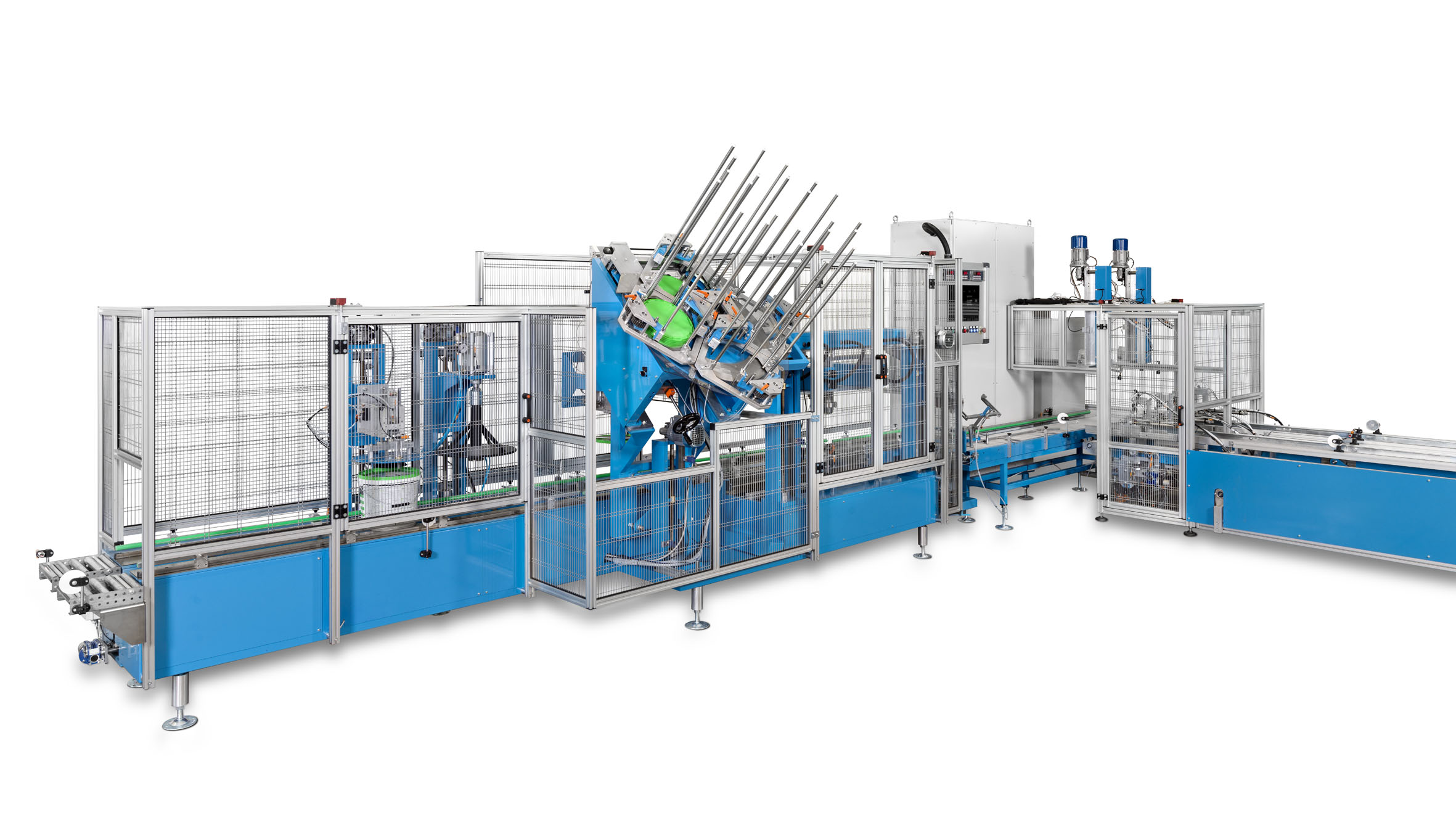

Experience the top of the range automatic filling system LINEA by Tecnopails

Designed to be fully configurable as a complete process filling line, this automatic high-speed filling machine boasts a wide range of optionals for varying pail sizes and types. It is ideal for small to big pails, jerry cans with press lid, screw cap, clamping lid or collar closures. Lids are distributed automatically and are pneumatically controlled by a pails-detection micro-switch.

Explore what make our machines tick, IMAESTRO

Unveil the brain behind our cutting-edge technology and explore the wonders of our exclusive user-friendly software, IMAESTRO. This remarkable proprietary software is designed to seamlessly operate a wide range of systems, from compact units to intricate industrial setups. Dive into the world of IMAESTRO and witness the power of innovation at your fingertips.

Meet the team

Drop by our booth and meet our agent Ayla Cuhadaroglu and the Odak team; they will be delighted to meet you and assist with any inquiries you may have about our systems, solutions, software, and services.

.png)

.jpg)

.jpg)

.png)

Farewell to IM GROUP’s “San Francesco”!

Jun 27 2025